In the early days of aviation, machine guns could not be mounted on or in the fuselage of aircraft due to fears of shooting off the propeller.

|

| This guy had a bad day |

One of the first attempts at solving this problem was mounting armor or bullet deflectors to the propeller. The bullet deflector was a popular concept that was used on a lot of different aircraft. A small metal wedge was fitted at the place where the bullets would hit the propeller, deflecting bullets away from the propeller.

|

| The bullet deflectors are the triangles mounted on the propeller. Note the interesting tray-fed machine gun. |

A slightly later solution to this problem was the Vickers Gunbus, called so because of its amazing armament of ... a single .303 Lewis machine gun (some crews upgraded the armament to 3 or 4 Lewis guns). The gun was mounted on a pivot and operated by the observer sitting in the front cockpit. Vickers got around the issue of shooting off their propeller by mounting the engine and propeller behind the cockpit. While it made the aircraft look strange, it actually worked really well.

|

| Gunbus! |

As the war progressed, though, the Gunbus became outclassed by newer fighters which boasted better climb rate and speed. This time, the solution to keeping the most important bit of your aircraft intact was to mount the machine gun on the upper wing, firing over the propeller. This allowed the aircraft to be smaller and lighter (no need for an observer/gunner) and more competitive as a fighter.

The Foster Mount, as it was known, worked quite well on the early Nieuport and Sopwith fighters. But there were still some major issues that needed to be fixed. The .303 Lewis gun that was used in the mountings had a magazine capacity of 97 rounds. While this seems like a lot, the gun could empty this in about 10.5 seconds. Once the magazine was empty, the pilot had to pivot the gun down and replace the magazine, something that was nearly impossible in a fast-paced air-to-air engagement.

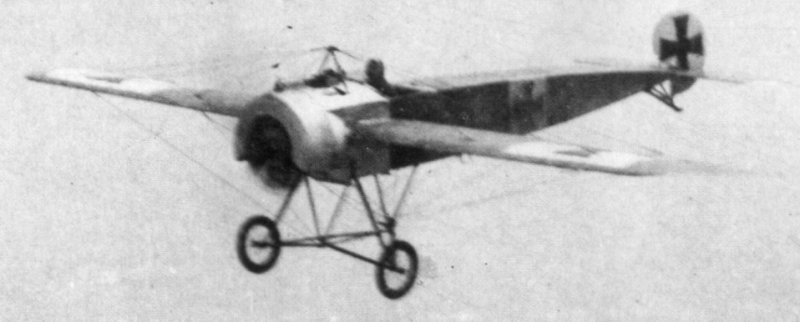

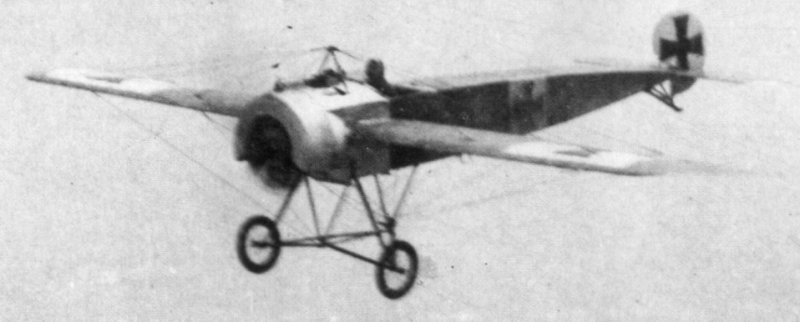

The best solution to this problem, used for the rest of WWI and WWII, was the interrupter gear. Basically, the engine driveshaft drove a cam that would prevent the gun from firing when the propeller was in front of it. Whenever the propeller was in front of the guns, the interrupter gear prevented the gun from firing. This mechanism was first used on the Fokker Eindecker, a small single-gun German fighter. The advantage gained by having a fixed forwards-firing gun was immediately visible. From July 1915 to early 1916 the Eindeckers gained total air superiority over the Allies, racking up a large amount of kills. This period was called the "Fokker Scourge" by Allied aviators.

|

| "Vrrrooooommm" -Fokker Eindecker |

Soon, however, Allied research into interrupters matched German technology, and the Eindeckers soon had worthy allied opponents in the sky. And by mid-1916 the Eindecker was all but obsolete, overtaken by new German and Allies types. Interrupter mechanisms led to a few innovations that benefited many military fields. Most machine guns of the time operated on an open-bolt cycle, which was mechanically simple but very hard to time precisely (imprecise timing will shoot off your propeller). A new type of machine gun, operating on a closed-bolt cycle, was adapted to interrupter mechanisms. These new guns were fed by an ammunition belt, unlike older aircraft guns, which used drum or box magazines. All of the ammunition could be connected together into a long belt (The Eindecker had 500 rounds), which allowed the pilot to focus on shooting down the enemy and not replacing the magazine every hundred rounds. Air-cooled machine guns also came to the forefront in aircraft design. Early machine guns were cooled by a water jacket around the barrel. While this worked well for ground troops, aircraft needed to remain light. Air-cooled machine guns were developed to fix this problem. Instead of being cooled by flowing water, the barrel was cooled by air rushing over it.

|

| Two MG 08 Machine Guns on a Fokker Triplane. The perforated sleeves for air-cooling the barrel are visible, as is the belt feed system to the right of the guns. |

Most interrupter systems operated off of a gear drive on the driveshaft that prevented the gun from firing when the propeller is in front of the gun. An important clarification must be made here: The interrupter does not sense if the propeller is in front of the gun. It is purely reliant on good timing. It happened a few times where the interrupter gear failed and the propeller was shot off. Overall, though, the interrupter gear proved to be a very important and influential innovation in the field of warplanes, influencing many other fields of engineering. Air-cooled belt-fed machine guns have become virtually the only type on the battlefield, and almost all fighter aircraft now have fixed forwards firing guns. The interrupter mechanism was used throughout WWII up until the advent of jet aircraft rendered it obsolete.

|

| A Bf-109E, one of Germany's best early-WWII fighters, gets it interrupter adjusted |

|

| A Lockheed P-80 Shooting Star, one of the first jet fighters. Evidently there is no propeller to get in the way of the six .50 Cal. machine guns, thus not needing an interrupter gear. |

2 comments:

The information was organized clearly with helpful images. Very interesting topic and I like the labels under your pictures to clarify the image. I think maybe next time, you could make the images smaller because it would be nice to read the passage while looking at the picture without a lot of scrolling. Nice blog!

Fascinating! Great images, good research. Evidently lots of effort was put into this.

Post a Comment